Construction jargon

Technical terms are often used in the construction of the new sea lock. We have listed the most commonly used terms for you.

Curious to see what will be where? Check our overview picture (pdf, in Dutch).

Anchor

The anchor is the construction by which the diaphragm wall of the lock chamber wall is fastened into the subsoil. Each anchor is approximately 40 metres long.

Bentonite

A mixture of water and clay used for the construction of the diaphragm walls.

Tubular pile

A long hollow steel pipe. Especially used for combi walls.

Caisson method

A structure consisting of cutting edges, a concrete floor and concrete side walls that will be sunk in a controlled manner.

Combi wall

A wall made of a combination of pipe piles and sheet piling.

Sheet pile wall

A retaining wall driven into the ground to withstand lateral earth and water pressures. The wall consists of single piles or steel panels connected to each other.

Doorstone

A cover plate to finish the wall nicely.

Gate chamber

The gate chamber is that part of the concrete lock structure into which a rolling gate is run to enable ships to enter (respectively, leave) the lock during the lockage process. OpenIJ is constructing two lock gate chambers on the southern side of the new sea lock into which the gates can be stored in ‘open’ position.

In the inner lock head (at the North Sea Canal side), OpenIJ is not only building the gate chamber for the operational lock gate, but also an on-site maintenance dock for the spare lock gate. That is why the inner head gate chamber is much larger than the outer head gate chamber (the chamber at the seaward side).

Gate recess

The gate recess is the vertical recess (slot) in the lock chamber wall directly opposite the gate chamber (the chamber into which the lock gate is stored in 'open' position). This vertical recess in the wall is necessary to create a watertight seal between lock chamber and lock gate.

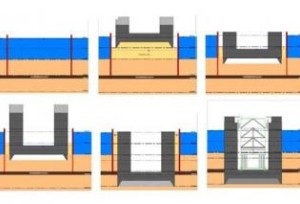

Diaphragm walls

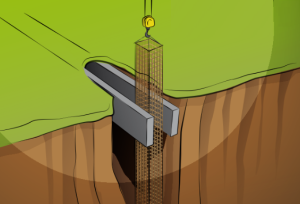

Diaphragm walls are dug out instead of driven into the soil by using a vibratory pile driver. For the construction of the New Sea Lock, special excavators are used for digging trenches of 7.5m long, 40m deep and 1.3-1.5m wide.

During the digging process, a support fluid (bentonite) is applied to prevent the walls of the trench from collapsing. Reinforcement steel is then installed after which the trench is filled with concrete. Because concrete is heavier than bentonite, the bentonite will be pushed to the surface from where it will be removed to be reused two to three times.

Lock sill

The lock sill (literally 'threshold') is a narrow horizontal concrete ledge, built on the bottom of the lock chamber, on top of which the rolling gates will run.

Fendering system

Bridges or locks create a narrowing of the waterway. A fendering system or a fender wall is a construction that helps to guide ships (either mechanically or visually) towards and through the narrow passage or entrance.

Cofferdam

A temporary enclosure built within a body of water and constructed to allow the enclosed area to be pumped dry.

Cut-off

Cut-offs are concrete walls constructed below the ground to prevent long-term sand seepage.

Lock chamber

The lock chamber is the watertight concrete enclosure between the lock gates.

Cutting edges

Concrete triangles of 2.5m high that form the contours of the lock gate recess.

Traverse

The traverse, built on top of the cofferdam, is a gantry-like structure onto which a crane will be installed. People can still continue to work under the traverse. The traverse acts as a moveable platform.

Digging up a diaphragm wall

When digging out a diaphragm wall, the top part of the diaphragm wall will be demolished. This is to make place for the anchoring construction and will be filled up with concrete to give the lock chamber wall its smooth appearance.